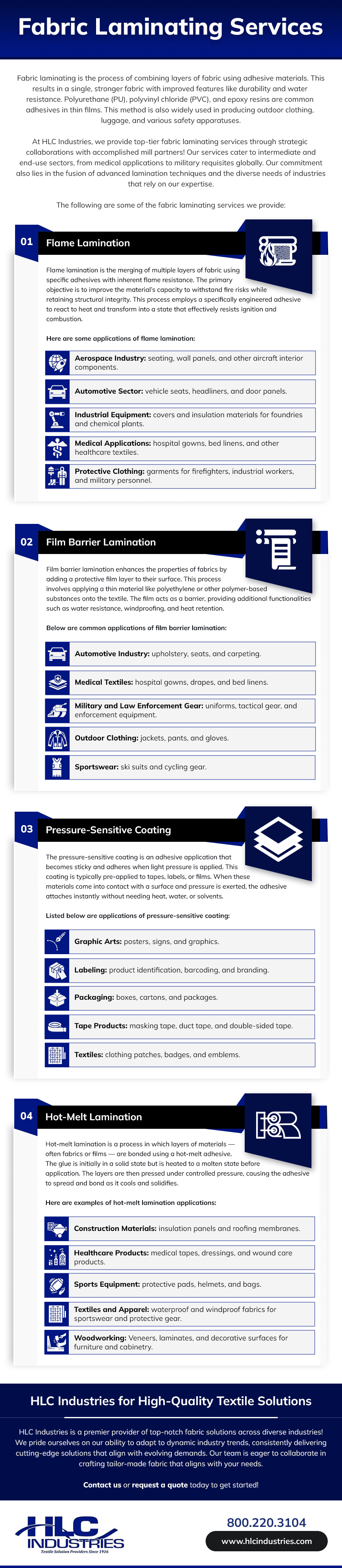

Fabric laminating is the process of combining layers of fabric using adhesive materials. This results in a single, stronger fabric with improved features like durability and water resistance. Polyurethane (PU), polyvinyl chloride (PVC), and epoxy resins are common adhesives in thin films. This method is also widely used in producing outdoor clothing, luggage, and various safety apparatuses.

At HLC Industries, we provide top-tier fabric laminating services through strategic collaborations with accomplished mill partners! Our services cater to intermediate and end-use sectors, from medical applications to military requisites globally. Our commitment also lies in the fusion of advanced lamination techniques and the diverse needs of industries that rely on our expertise.

The following are some of the fabric laminating services we provide:

Flame Lamination

Flame lamination is the merging of multiple layers of fabric using specific adhesives with inherent flame resistance. The primary objective is to improve the material’s capacity to withstand fire risks while retaining structural integrity. This process employs a specifically engineered adhesive to react to heat and transform into a state that effectively resists ignition and combustion.

Here are some applications of flame lamination:

- Aerospace industry: seating, wall panels, and other aircraft interior components

- Automotive sector: vehicle seats, headliners, and door panels

- Industrial equipment: covers and insulation materials for foundries and chemical plants

- Medical applications: hospital gowns, bed linens, and other healthcare textiles

- Protective clothing: garments for firefighters, industrial workers, and military personnel

Film Barrier Lamination

Film barrier lamination enhances the properties of fabrics by adding a protective film layer to their surface. This process involves applying a thin material like polyethylene or other polymer-based substances onto the textile. The film acts as a barrier, providing additional functionalities such as water resistance, windproofing, and heat retention.

Below are common applications of film barrier lamination:

- Automotive industry: upholstery, seats, and carpeting

- Medical textiles: hospital gowns, drapes, and bed linens

- Military and law enforcement gear: uniforms, tactical gear, and enforcement equipment

- Outdoor clothing: jackets, pants, and gloves

- Sportswear: ski suits and cycling gear

Pressure-Sensitive Coating

The pressure-sensitive coating is an adhesive application that becomes sticky and adheres when light pressure is applied. This coating is typically pre-applied to tapes, labels, or films. When these materials come into contact with a surface and pressure is exerted, the adhesive attaches instantly without needing heat, water, or solvents.

Listed below are applications of pressure-sensitive coating:

- Graphic arts: posters, signs, and graphics

- Labeling: product identification, barcoding, and branding

- Packaging: boxes, cartons, and packages

- Tape products: masking tape, duct tape, and double-sided tape

- Textiles: clothing patches, badges, and emblems

Hot-Melt Lamination

Hot-melt lamination is a process in which layers of materials — often fabrics or films — are bonded using a hot-melt adhesive. The glue is initially in a solid state but is heated to a molten state before application. The layers are then pressed under controlled pressure, causing the adhesive to spread and bond as it cools and solidifies.

Here are examples of hot-melt lamination applications:

- Construction materials: insulation panels and roofing membranes

- Healthcare products: medical tapes, dressings, and wound care products

- Sports equipment: protective pads, helmets, and bags

- Textiles and apparel: waterproof and windproof fabrics for sportswear and protective gear

- Woodworking: veneers, laminates, and decorative surfaces for furniture and cabinetry

HLC Industries for High-Quality Textile Solutions

HLC Industries is a premier provider of top-notch fabric solutions across diverse industries! We pride ourselves on our ability to adapt to dynamic industry trends, consistently delivering cutting-edge solutions that align with evolving demands. Our team is eager to collaborate in crafting tailor-made fabric that aligns with your needs.

Contact us or request a quote today to get started!